Econyl process 350764-Econyl process

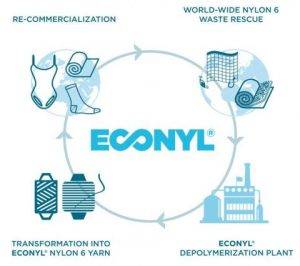

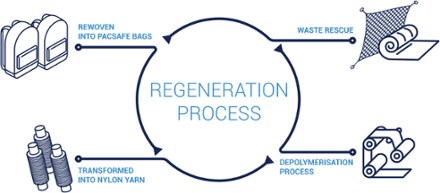

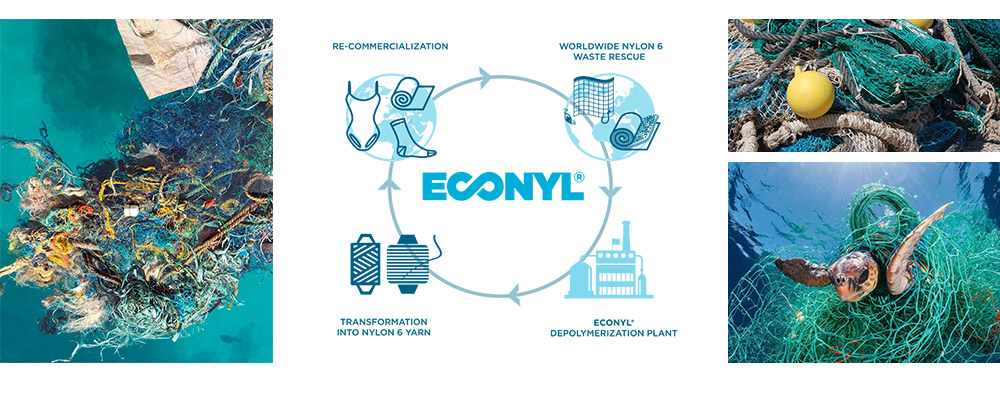

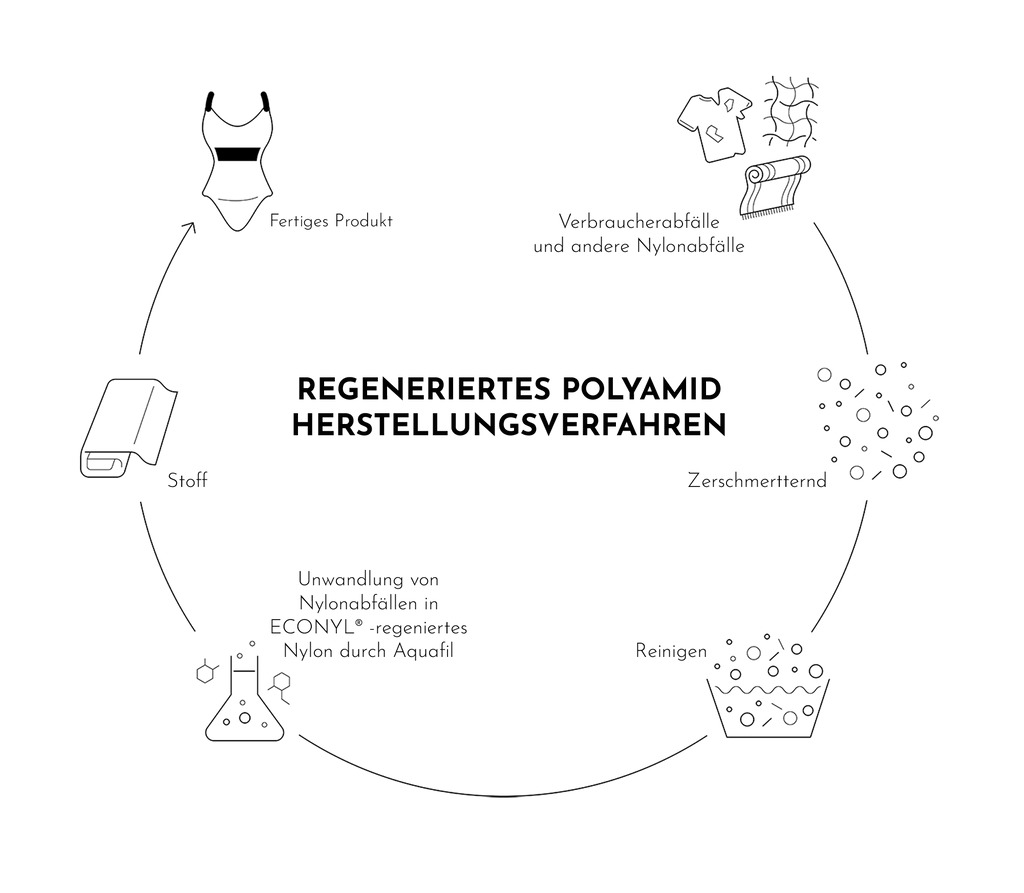

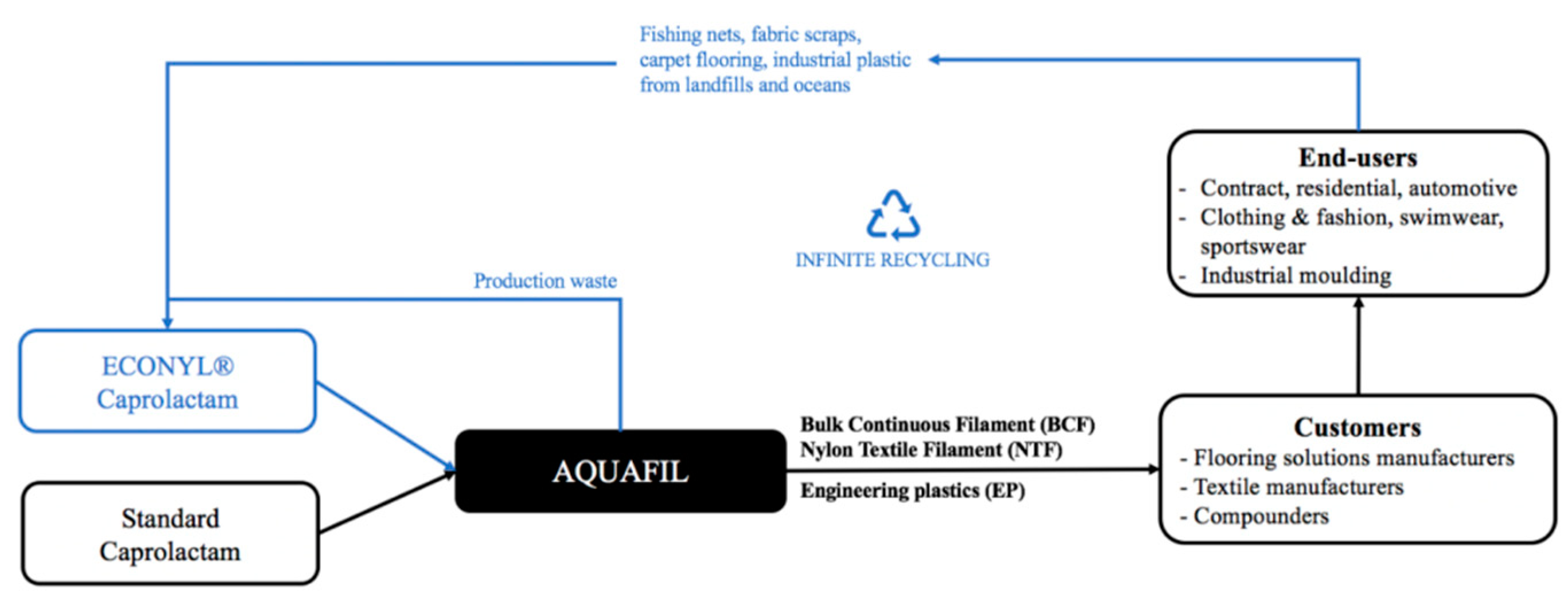

ECONYL® is a regeneratednylon yarn that can be recycled an indefinite number of times without affecting the quality of the material ECONYL® yarn is made of recycling discarded plastic that has been collected from landfill sites and oceans across the whole planet PRODUCTION PROCESS 1 Gathering of waste materials fishing nets, discardedECONYL, created by Italian firm Aquafil, uses synthetic waste such as industrial plastic, waste fabric, and fishing nets from oceans, then recycles and regenerates them into a new nylon yarn that is exactly the same quality as virgin nylon This regeneration system focuses on 6 steps that form a closed loop which uses less water and createsA part of this, ECONYL® and Aquafil have developed a unique Regeneration System, a process Aquafil to produce 100% regenerated Nylon yarn using waste material instead of fossil raw material The ECONYL® regenerated yarn is now use by the most important brands both in the carpet industry and the textile and fashion one

The Econyl Regeneration System Youtube

Econyl process

Econyl process-2 days ago The production process for econyl starts with collecting waste like carpet flooring, fabric scraps, fishing nets, and industrial plastic from all over the world After it is collected, the waste is cleaned and sorted to recover all nylon possible Through a regeneration and purification process, nylon waste is then restored to its original form With this process, econyl has the capability of being recycled infinitely Econyl is a young material that became available on the market in

Sustainability In Textiles Which Road To Follow Special Textiles 19 Arsutoria Magazine

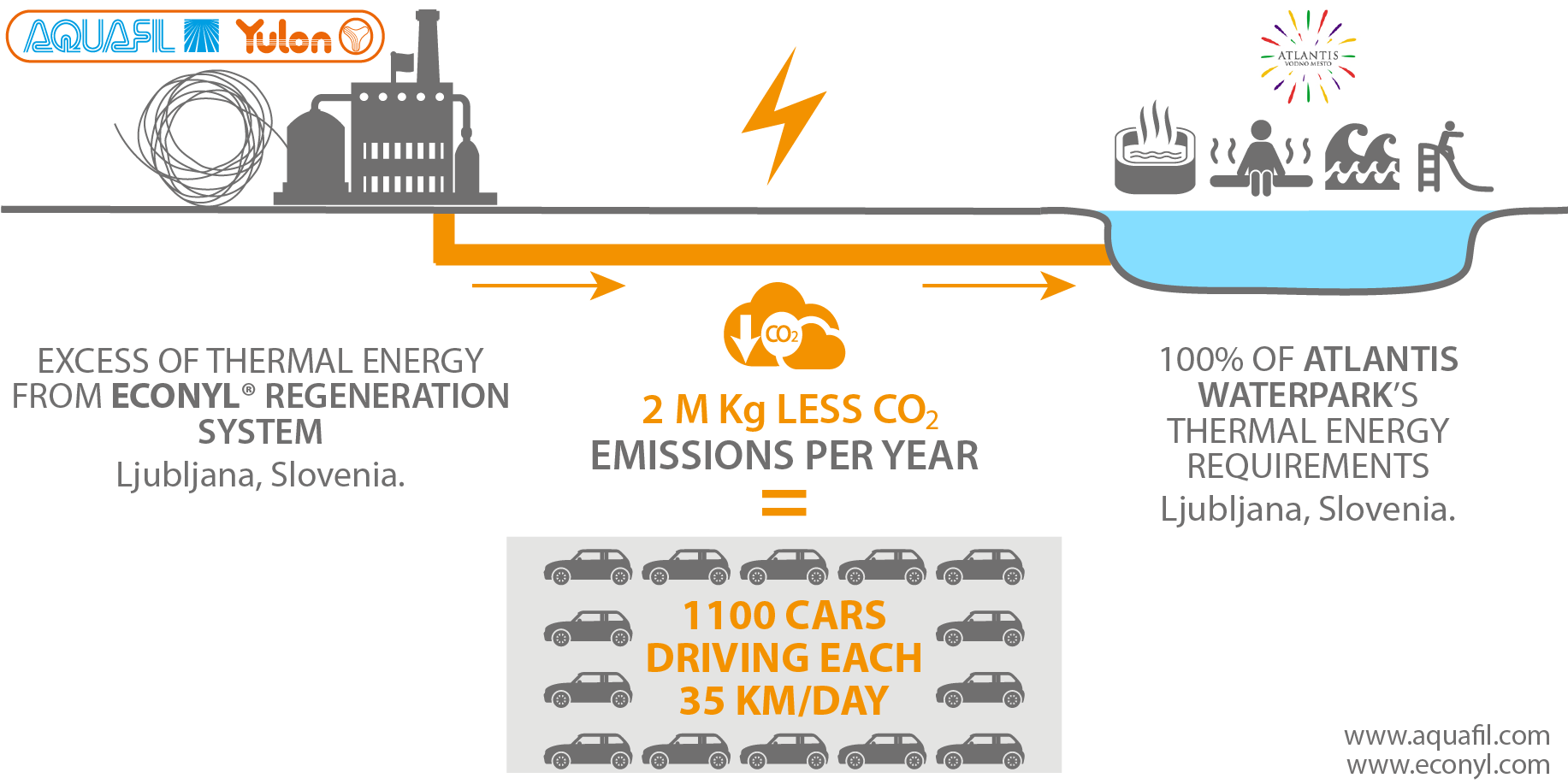

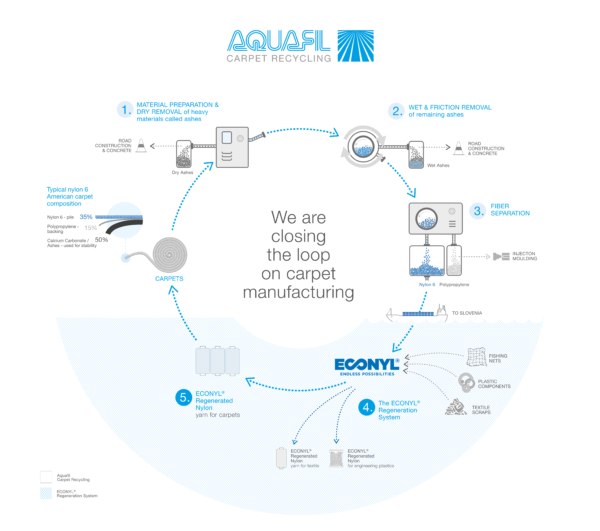

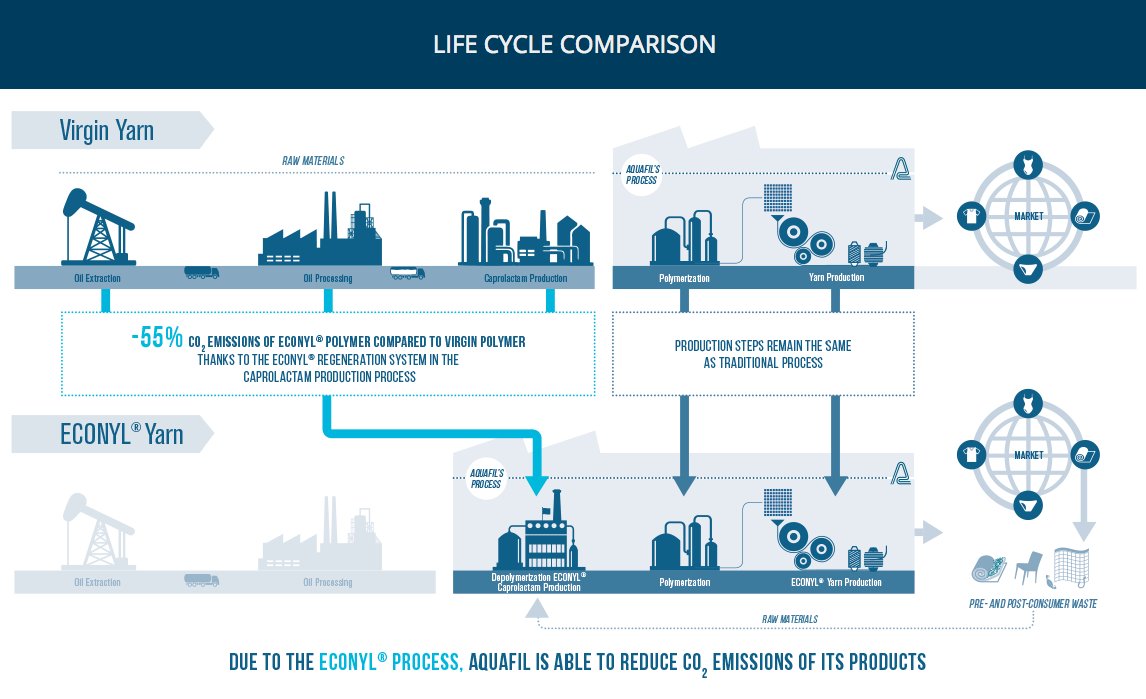

The 6 steps of the ECONYL® Regeneration System that allows to recover nylon 6 waste and transform it into ECONYL® regenerated nylon yarn for new products Di ECONYL® Regenerated Nylon is an important solution for the planet as for every 10,000 tons of ECONYL® raw material, 70,000 barrels of crude oil are saved, and 65,100 tonnes of CO2 eq emissions are avoided Additionally, the process of created ECONYL® reduced the global warming impact of nylon by up to 90% when compared with traditional nylon ECONYL yarn reduces the energy demand of traditional yarn by 45% As you can see, the ecobenefits of ECONYL go well beyond simply recycling!

Depolymerisation through the ECONYL® process is the next logical step for Aquafil However, there is a tendency to overplay the link between 'innovation' and technology, when in fact the company is realising the benefits of a closed loop model right now, without relying on radical jumps in technology, or waiting for a revolutionary The raw nylon material is then turned into the yarn, known as ECONYL® Throughout the process, other byproducts such as nonnylon, metallic materials or copper sulphate which is used forThe ECONYL® process Part 1 RESCUE The ECONYL® Regeneration System starts with rescuing waste from oceans and landfills all over the world The waste is then sorted and cleaned to recover all of the nylon possible Part 2 REGENERATE

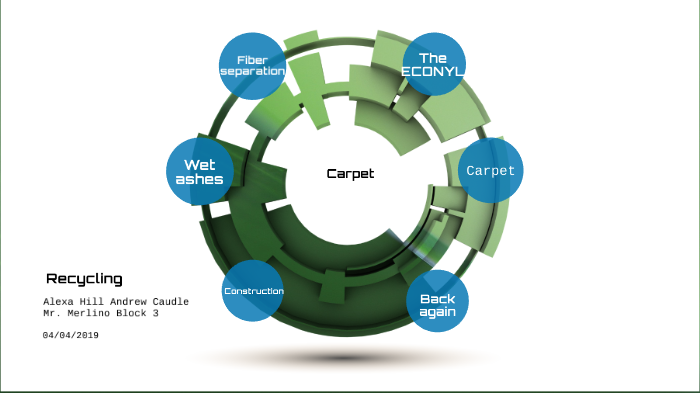

They can each process up to tons of carpet annually and break old carpets down into three main components polypropylene (PP), Nylon 6, and calcium carbonate 1 Nylon 6 is sent to the ECONYL® Regeneration Process in Slovenia with other waste, like discarded fishing nets or textile waste, to make ECONYL® nylon yarn 2Depending on the process, a different building block (monomer or oligomer) is recovered and then repolymerized to create a new, virginquality material Mechanical recycling is more established, but chemical recycling allows for greater flexibility in quality, color and performance in the final product nylon and ECONYL®, but also withAs mentioned, the process of creating ECONYL is new and we're confident that further developments will be made to protect the planet and our resources

Our Commitment For A Great Achievement Youtube

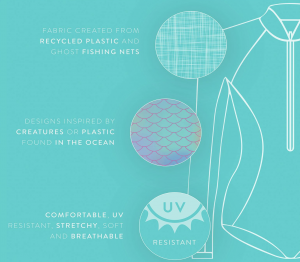

Recycled Plastic Fabric Econyl Carvico Vita Ocean Mimic

The process can even be used on blended materials such as a nylon/elastane blends Unfortunately, the current process only recovers the nylon from these blended fabrics Hopefully, in the future, this technology can be developed Once the Econyl yarns are produced they can be used to create many different products Econyl is not moisturewicking, and it will melt if washed at high temperatures How Is Econyl Fabric Made?ECONYL® Endless Possibilities Our appetite to create new products and buy new products is infinite The planet's resources aren't But it's okay because we can have both new products and a better environment Nylon waste, otherwise polluting the Earth, is transformed into ECONYL® regenerated nylon It's exactly the same as brand new

Recycled Fabrics Regenerated Nylon For Eco Friendly Fabrics In Econyl

What Is Econyl Fabric Properties How Its Made And Where Sewport

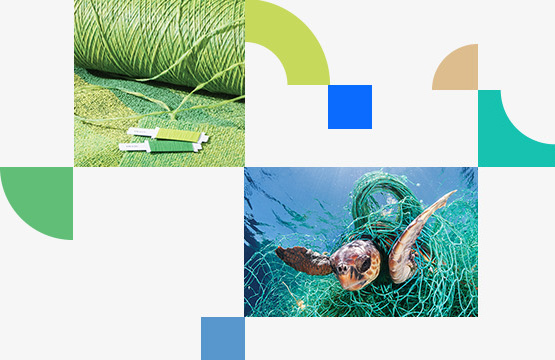

Aquafil has not disclosed the exact processes it uses to make Econyl The only information available details a vague process of capturing nylon waste, subjecting it to depolymerization, and reconstitution of the resulting material intoThe ECONYL® regeneration process transforms what was waste into a new source of opportunities to be implemented in the fashion and furniture industries Here can find more informationsThe Econyl regeneration system recovers waste which would otherwise end up in landfills or oceans (fishing nets), causing serious damage to the entire ecosystem and can be regenerated an infinite number of times to produce new polymers with technical characteristics and quality equivalent to products obtained from fossil materials

Sustainability In Textiles Which Road To Follow Special Textiles 19 Arsutoria Magazine

1

ECONYL® nylon process reduces emissions in production by 90 per cent compared with the material produced from oil; ECONYL® production process is continuously improved and this analysis took into consideration the most representative and specific data available From a general point of view all of the plants are described using primary data from January 16December 16, with exception of ECONYL® plant energy consumptionThe ECONYL® regenerated nylon process When creating something as diverse and as powerful as this, there is naturally a lot of work involved At the moment, the process for creating ECONYL® yarn involves the following steps 1 The process starts off by rescuing as much waste product as is possible this often includes things like carpet

Econyl Partnership Rewild

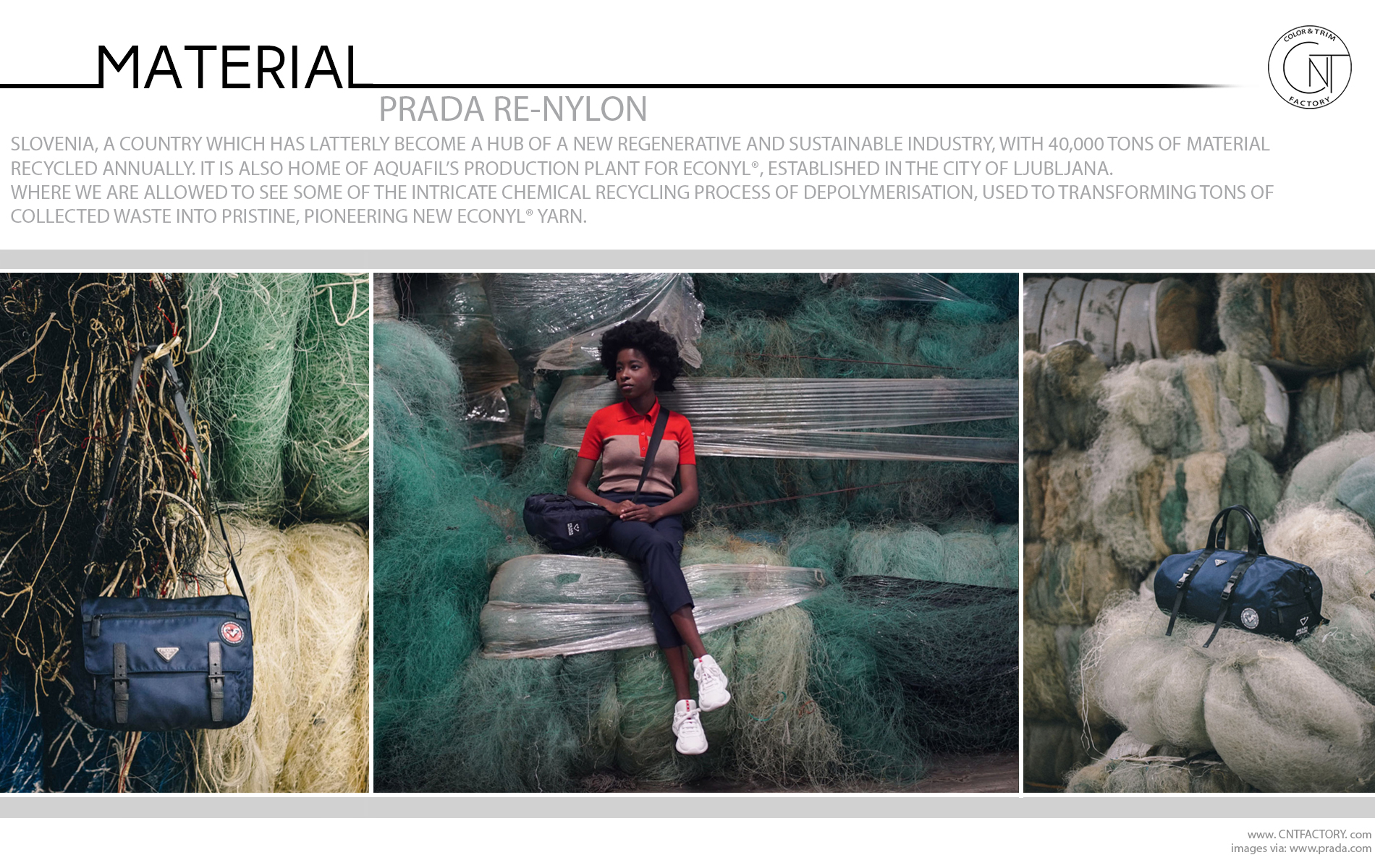

Prada Renylon Econyl Automotive Color Trim Material Trends

ECONYL® regenerated nylon is a product that can help you close the loop Made from waste, it's infinitely recyclable and can unleash infinite possibilities for makers, creators and consumers It's all part of the ECONYL® brand vision to make the world a better place by pioneering closed loop regeneration processes and delivering sustainable Econyl is particularly prized for its high level of traceability since information about its sourcing and production processes are publicly available That's crucial to the recycling process because, by the time the material is in the final product, EconylECONYL® production process is continuously improved and this analysis took into consideration the most representative and specific data available From a general point of view, all of the plants are described using primary data from January 16December 16, with exception of ECONYL® plant energy consumption

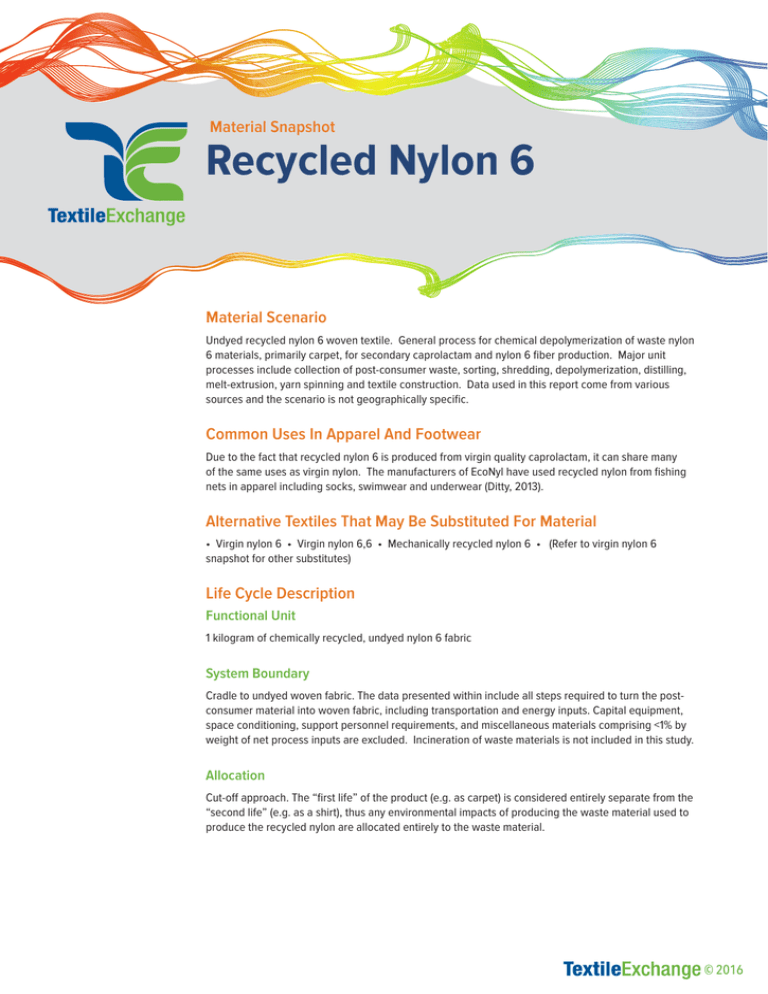

Recycled Nylon 6 Textile Exchange

The Process Econyl

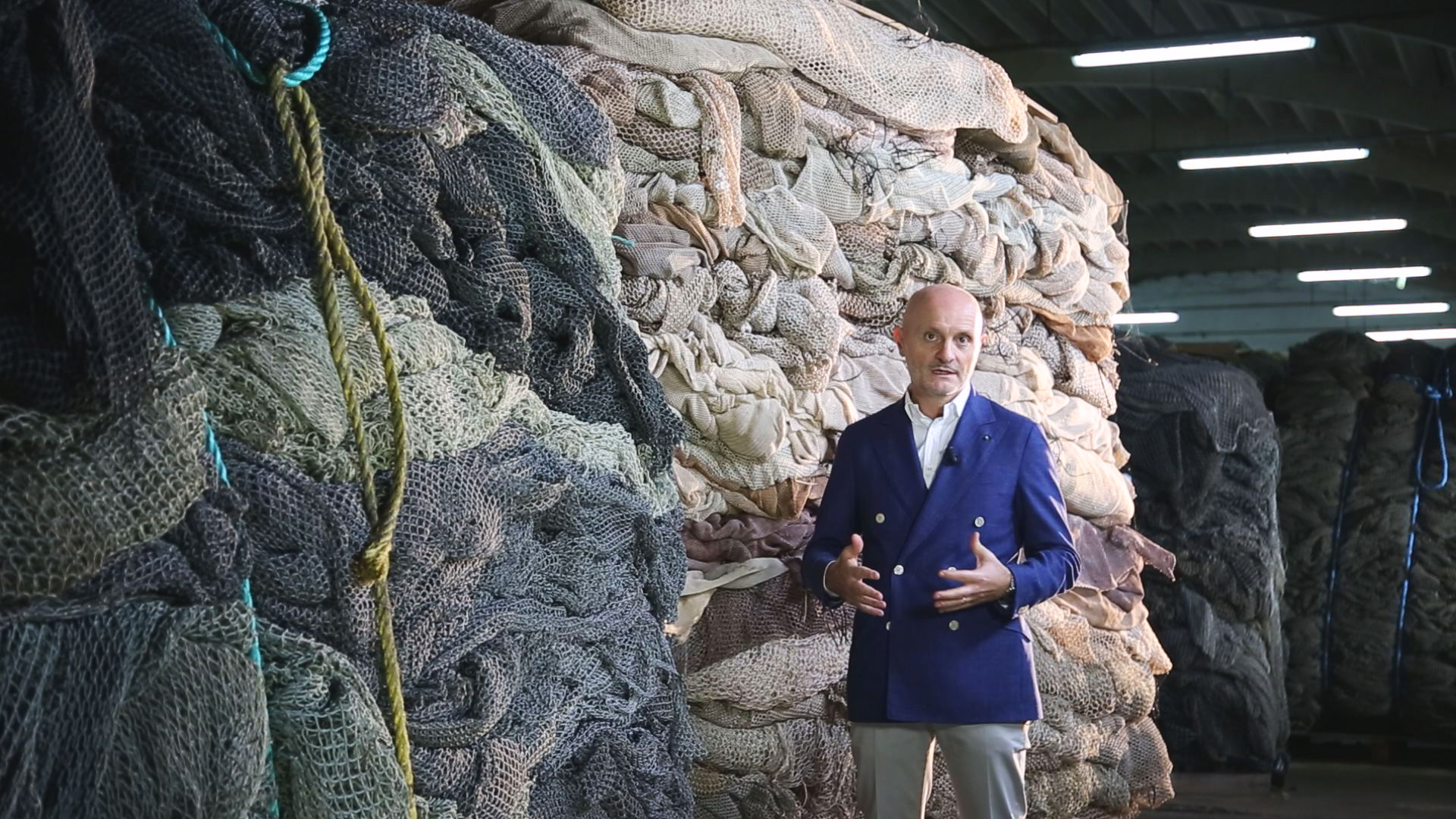

Kelly a top reclaimed fishing nets at the ECONYL® Intake Center, Slovenia In late 14, in an effort to get a deeper understanding of the process, Kelly and the Outerknown production team traveled to the ECONYL® intake center in Slovenia There, they got a first hand look at Aquafil's breakthough ECONYL® processThe innovative ECONYL® Regeneration System is based on sustainable chemistry with this industrial process, the nylon contained in waste, such as carpets, fabrics scraps fishing nets and others, is transformed back into raw material without any loss of quality At the moment there are two main waste streams that are relevant for the production About ECONYL ECONYL is a type of regenerated nylon made from waste from landfills and oceansGoing beyond the conventional recycling process, ECONYL uses regeneration, which ensures that the new fabric is exactly the same as virgin raw nylon — meaning ECONYL has likenew qualities and can be infinitely recycled and recreated into new products

Aquafil Julon With The Econyl Regeneration System Launches A New Kind Of Collaboration

Post Savant

Aquafil's Econyl process achieves 100 percent yield By returning the carpeting back to caprolactam, Aquafil is creating a material that can be turned into anything made from nylon, including clothing, sporting goods or injection molded products — just like in nature where decaying leaves can become nutrients for anything from new trees toSuppliers Aquafil is the supplier behind ECONYL® an innovative nylon yarn, produced entirely from recovered fishnets and other nylon waste Through an advanced recycling process, the waste materials are broken down to their rawmaterial state and then rebuilt with the exact same performance as nylon produced from fossil materials Polyamide 6 waste, like old carpets and fishing nets, is needed to create Econyl fabric These can be rescued from both landfills and waterways Once the waste has been collected, it goes through a rigorous process before it can be used to make clothing

Recycled Fabrics Regenerated Nylon For Eco Friendly Fabrics In Econyl

Prada Renylon Econyl Automotive Color Trim Material Trends

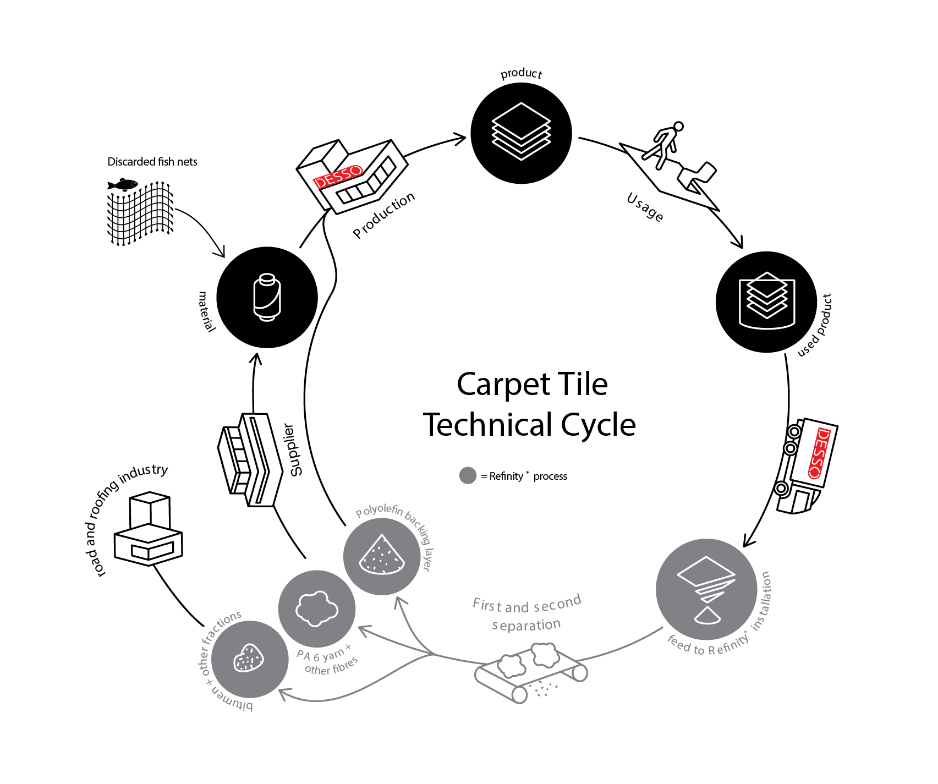

Econyl, also referred to as recycled or waste nylon, is made from plastic pollutants like abandoned fishing nets and scrap As we are forced to find more suitable and sustainable alternatives to popular synthetic fabrics, Italian textile company Aquafil may just have the answer with their recycled and regenerated nylon product "Econyl" Aquafil is the developer of the Econyl regeneration system, a process which separates polyamide waste from carpets, enabling it to be reused Econyl yarn has been an important commercial driver for the company, which indicates that "consumers and manufacturers clearly want to play an active role in the circular economy," Aquafil chairmanThe ECONYL® Regeneration System is a unique process that allows Aquafil to produce 100% regenerated Nylon yarn using waste material instead of fossil raw mat

Econyl A Special Nylon That Is Infinitely Recyclable

Eco Manola

The ECONYL® Regeneration System is a unique process that allows Aquafil to produce 100% regenerated Nylon yarn using waste material instead of fossil raw material The ECONYL® regenerated yarn is now used by the most important brands both in the carpet industry and the textile and fashion one But how was the beginning of this adventure?Milan, Aquafil shares are now listed on the Italian stock exchange with the aim of a circular venture, following a production model inspired by nature and its infinite capacity for regeneration A vision based on concrete achievements like ECONYL® 100% regenerated and 100% performance nylon yarnECONYL® regenerated nylon is 100% made from pre and postconsumer waste Below we cover the ECONYL® Process 1 RESCUE A variety of recovered materials such as abandoned ghost fishing nets, fabric scraps from mills, carpet flooring and industrial plastic are collected from oceans and landfills globally This is an important step because it

Econyl A Special Nylon That Is Infinitely Recyclable

Aquafil The Econyl Yarn

The ECONYL® brand is not just a yarn but represents a new way of thinking, a way to reconcile the desire for innovation with the constant commitment of the Company to protect the environment The ECONYL® regeneration process transforms what was waste into a new source of opportunities to be implemented in the fashion and furniture industriesJaguar Land Rover is committed to offering a wider choice of responsibly sourced materials with the same luxurious feelThus, the fishing nets recovered, together with some other materials ( carpet fluff, tulle etc ) are delivered to Aquafil SpA regeneration plant where, thanks to a sophisticated and complex process, the above mentioned materials are turned into ECONYL ®, a new polyamide yarn boasting the same features as virgin nylon in terms of performance and quality, but with the plus of not having been

The Econyl Regeneration System Edi Kraus General Manager Aquafilslo Pdf Free Download

Welcome Econyl Regenerated Nylon

Econyl regenerated nylon is a product introduced in 11 by Aquafil It is made entirely from ocean and landfill waste, such as industrial plastic, fabric scraps from clothing manufacturing companies, old carpets and "ghost nets" (lost or abandoned fishing nets) The product has been used by Stella McCartney (handbag linings, backpacks, outerware, etc), Kelly Slater's label Outerknown, Results This 4stage process has seen that for every 10,000 tons of ECONYL® raw material, they are able to save 70,000 barrels of crude oil and avoid 57,100 tonnes of CO2 emissionsIt reduces the impact on climate and contribution to warming by up to 80% compared with materials from oil Diving deeper With a brief synopsis of the ECONYL® regeneration process With the ECONYL® process, this material can be recovered – eg from carpet fluff (the upper part of carpets), abandoned or spent fishing nets (from all over the world with the help of Healthy Seas Initiative) – and regenerated, giving it a new

The Process Econyl

)

What Is Econyl Regenerated Nylon

Econyl® regenerated nylon is 100% recycled yarn made from nylon waste such as old carpets, fabric scraps and fishing nets Through the regeneration process, Econyl® yarn never loses its virgin qualities which means it can be recycled an infinite amount of times, making it a perfect sustainable fibre solution RESCUE Apparently, this process is undertaken to remove any impurities from existing nylon fiber, and it's unclear whether the production of Econyl involves reacting diamine acid with adipic acid as is the case in normal nylon production

Celebrating Nine Years Of Econyl Nylon With Nine Highlights And A Glimpse Into The Future By Econyl Brand Medium

Safilo And Aquafil Together To Produce Eco Sustainable Eyewear Textilefuture

The Future Of Sustainable Swimwear Fabrics Spotlight On Econyl Thegreenlabels Com

Aquafil The Econyl Yarn

Sustainability Hoessee

Regeneration Means To Revive Or Rebuild It Gives A Better Quality End Product Compared To Recycling When It Comes To Yarn We Work With Econyl To Make This Happen The Process Is As Follows Econyl Is Turning Waste Into First Grade Nylon Yarn Which

What Is Econyl Fabric Properties How Its Made And Where Sewport

The Process Econyl

The Process Econyl

A Journey Into The Econyl Regeneration System Design Journal From Dctuk Carpet Tile News

Econyl Ecorebels

Econyl Int Pacsafe Com

The Buzz About Econyl The Other Bag

Econyl Circular Story Of Our Swimsuits Mimi August

Carpet Concept Develops New Carpets Made With Econyl Yarn

Circular Stories Econyl Fabric Designed With The End In Mind Everyday Recycler

Desso S 13 Sustainability Report Highlights Econyl Brand And Healthy Seas Collaboration Econyl

The Process Econyl

Recycled Plastic Fabric Econyl Carvico Vita Ocean Mimic

Products Healthy Seas

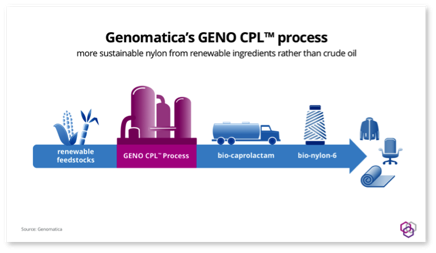

Aquafil And Genomatica Collaborate On Bio Nylon

Econyl The Infinitely Recyclable Nylon Yarn Livingcircular

Jaguar Land Rover Will Use Plastic Waste In Next Generation Sustainable Luxury Interiors Jlr Corporate Website

Recycled Plastic Fabric Econyl Carvico Vita Ocean Mimic

Pacsafe Econyl Series Rei Co Op

The Future Of Sustainable Swimwear Fabrics Spotlight On Econyl Thegreenlabels Com

1

Material Guide What Is Econyl Supplycompass

Econyl

What Is Econyl

15 Our Recycled Material Ideas Rugs On Carpet Regeneration Material

What Is Econyl Fabric Properties How Its Made And Where Sewport

The Econyl Regeneration System Youtube

Recycled Nylon Kampos

)

What Is Econyl Regenerated Nylon

The Process Econyl

Econyl Archives Fashion Revolution Fashion Revolution

Life Cycle Thinking Approach Euratex

Turning Waste Into Nylon Outerknown

A Journey Into The Econyl Regeneration System Design Journal From Dctuk Carpet Tile News

Sustainable Swimwear And Fabrics Auguste The Label

The Buzz About Econyl The Other Bag

Advances And Approaches For Chemical Recycling Of Plastic Waste Thiounn Journal Of Polymer Science Wiley Online Library

Econyl Int Pacsafe Com

Eco Fabric Sqorpios

Sustainable Swimwear Made From Recycled Ocean Plastic Waste Kaly Ora

Recycling Process Of Carpet By Alexa Hill

Figure 3 1 From Options For Closing The Loop For Plastic Debris Environmental Analysis Of Beach Clean Up And Waste Treatments Semantic Scholar

A Journey Into The Econyl Regeneration System Econyl

The Process Econyl

Econyl Wearenativ

About Us Econyl

Econyl Futerra

Life Cycle Thinking For Conscious Consumers By Econyl Brand Medium

Eco Sea Foam Fingerscrossed

Econyl

Arket Material Econyl Milled

Menestho Sustainable Designer Swimwear Econyl Endless Possibilities

What Is Econyl Regenerated Nylon

Econyl Brand The Econyl Regeneration Process From 100 Waste To Sustainabletextiles In 4 Simple Steps Circulareconomy

Lahco Renegerated Polyamide

The Dangerous Snorkelling Club Ocean Clean Up Divers Do While Surfer Dudes Don T

Econyl A Special Nylon That Is Infinitely Recyclable

Econyl Circular Story Of Our Swimsuits Mimi August

Medium What A Journey Closing The Loop On Carpet Manufacturing Econyl

Econyl Saving The Planet One Fabric At A Time Unika Custom Swimwear

Econyl Process Bi Eco Fashion

Meet Econyl The High Quality Regenerated Nylon Yarn European Circular Economy Stakeholder Platform

Recycled Nylon 6 Textile Exchange

What Is Econyl Fabric Properties How Its Made And Where Sewport

Aquafil Our Commitment

Sustainability Free Full Text Modern Circular Economy Corporate Strategy Supply Chain And Industrial Symbiosis Html

Jaguar Land Rover Will Use Plastic Waste In Next Generation Sustainable Luxury Interiors Jlr Media Newsroom

S S Spotlight Econyl Sustainable Social Sustainable Business Lifestyle

1

Econyl A Nylon Thread Made From Plastic Waste Plastics Le Mag

Our Eco Friendly Materials Halia Lifestyle

What Is Econyl Fabric Properties How Its Made And Where Sewport

Circular Economy Eu Excellent Case Study Of Circulareconomy Industry Transformation The Econyl Project T Co U6ab1jg3gz

Econyl Process Fighetti

A Journey Into The Econyl Regeneration System Econyl

Circular Stories Econyl Fabric Designed With The End In Mind Everyday Recycler

コメント

コメントを投稿